Choose a country to view content specific to your location

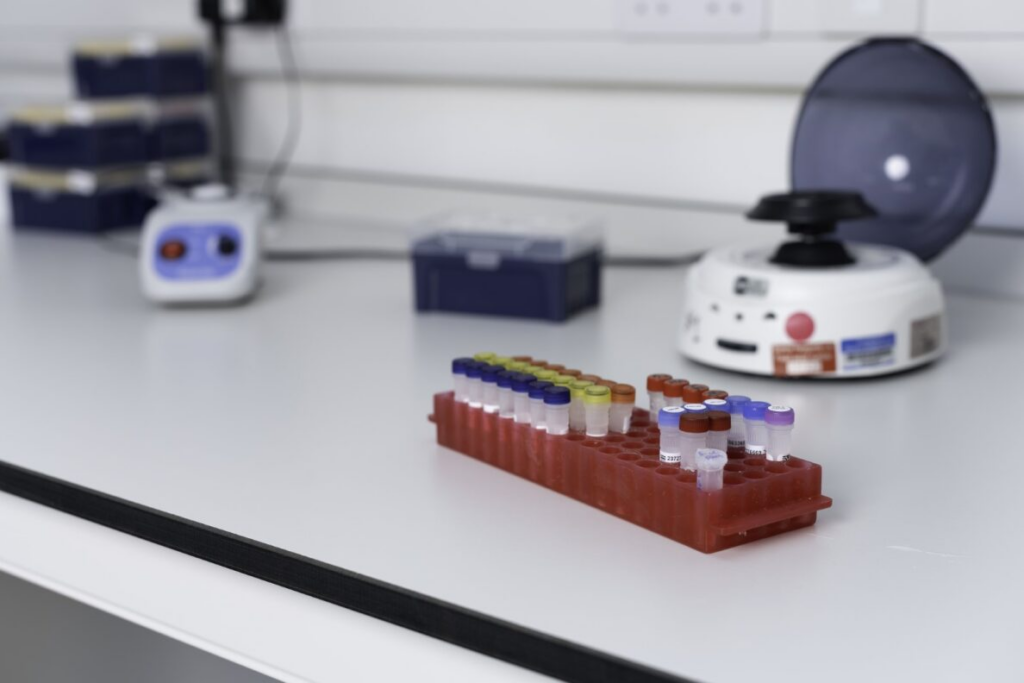

Meridian is a trusted molecular reagent manufacturer, delivering high-quality molecular diagnostic reagents and analytical reagents for research, clinical, and industrial applications. Our products support disease diagnosis, therapeutic discovery, and the development of tests for environmental, food, and cosmetic safety.

We offer a broad portfolio of PCR and RT-qPCR enzymes, DNA polymerases for PCR, reverse transcriptase enzymes, and buffer systems tailored for IVD assay development and optimization.

Meridian also provides ready-to-use PCR master mixes, including inhibitor-tolerant qPCR master mixes, air-dryable point-of-care molecular reagents, liquid ambient-stable master mixes, lyophilized PCR master mixes, and glycerol-free enzymes. Our isothermal amplification enzymes and LAMP master mixes enable reliable performance in one-step RT-qPCR and multiplex qPCR workflows.

From air-dryable POC PCR reagents to ambient-stable PCR master mixes, Meridian reagents are designed for efficiency, stability, and consistent results. Partner with us, a leading reagent supplier for molecular products that accelerate innovation and simplify assay workflows.

Not seeing what you’re looking for? Inquire about a new product

At Meridian, we don’t just supply reagents—we collaborate with you to develop, scale, and optimize your assays. From qPCR to NGS, our experts deliver customized solutions that enhance stability, streamline workflows, and get your diagnostics to market faster. Partner with us and bring your next innovation to life.

Click the play button on the left to watch a behind scenes look at our custom services.

Meridian has high-concentration, glycerol-free and lyo-ready enzyme and mixes, formulated for lyophilization or air-drying, for ambient temperature shipping and storage, extending shelf-life and increased flexibility in sample volume, internal quality controls to monitor extraction and co-purification of inhibitor in qPCR/RT-qPCR assays, as well as a unique mix designed for direct qPCR and LAMP from a variety of crude clinical specimens (e.g. blood, saliva, urine and stool).

We strive to provide our customers with solutions they need when they need it – from novel antigens and antibodies to major disease outbreaks such as Zika and SARS-CoV-2 to pioneering the market with our innovative air-dried qPCR/RT-qPCR mixes. We take pride in providing our customers with unparalleled support, customer service, and quality.

Quality

Scale

Speed

Dependability

Reagent Solutions for Molecular Diagnostics

Glycerol is used with most enzymes as a cryoprotectant and stabilizer. The presence of glycerol prevents the formation of ice crystals during freezing that can damage enzymes. If glycerol is removed, it needs to be substituted with stabilizers and enhancers that will do the same job. Lyophilization and air drying on the other hand requires the enzyme to be stable at very low or very high temperatures and maintain their activity after the water molecules have been removed. This requires a different set of excipients that will protect the enzyme during this process. Glycerol-free enzymes do not have these excipients, and these will need to be added prior to lyophilization or air drying.

High-concentration enzymes help reduce volumes when drying down, making the process faster, they also reduce volumes in microfluidic, cartridges and point of care (POC) devices, allowing for more sample to be added. They facilitate optimization and can speed up the reaction (as long as there is substrate available to bind to), increasing sensitivity and yield, as a result, they can be employed in a wide range of assay formats, allowing more flexibility for development and cost saving during commercialization.

Lyophilization is done by freezing and sublimation in a vacuum, forming a cake or bead, it has very low viscosity and up to 99% of the moisture is removed. Drying normally take 18-24 hours and requires cryo-excipients that protect the enzymes during the freezing. The reagents can be lyophilized to a bead or a cake format.

Air-drying is done by heating in a convection oven, forming a highly viscous pellet, with about 95% of the moisture removed. Drying normally take less than 2 hours and requires heat protecting excipients that protect the enzymes at higher temperatures. The reagents can be air-dried to a soft viscous format.

Lyophilization and air-drying helps to extend the product’s shelf life, enhance the stability of the reagents at higher temperatures, and allows for convenient and accurate dispensing of the reagents. After drying, the reagents are easily reconstituted with sample material.

Yes, reaction conditions are the same and they will produce the same results, this means that the liquid mixes can be used to create SOPs if you do not want to dry down and then later if drying is required (for example to increase sensitivity), the SOP can be updated for drying, it does not require completely new SOPs to be written, but excipients will need to be added.

Following drying in the presence or absence of a buffer containing excipients, primers/probes, most or our mixes should be stable for a minimum of 24 months at ambient temperature. Following rehydration, the assay reproducibility, sensitivity, and robustness should be the same as for a freshly made liquid mix.

No, our lyo-excipients are proprietary, if you require a buffer that contains lyo-excipients, we have the Lyo-Ready qPCR Buffer, 2.5x (MDX022).

Have questions about a product? Want to learn more about Meridian’s molecular or immunoassay reagent portfolio? We want to hear from you!

By submitting your information in this form, you agree that your personal information may be stored and processed in any country where we have facilities or service providers, and by using our “Contact Us” page you agree to the transfer of information to countries outside of your country of residence, including to the United States, which may provide for different data protection rules than in your country. The information you submit will be governed by our Privacy Statement.

| Specimen Type |

|---|

| Application |

| Catalog |

| Sizes |

| Wet(Liquid) |

| Air-Dryable |

| Glycerol-Free |

| Lyo-Ready |

| Concentration |

| High Concentration |

| Description |

| Request Sample |